THE ULTIMATE IN FABRICS. IT ALL BEGAN WITH COVERDINE.

Back in the 1940s when our trouser business really started to grow, the cloth responsible for our wonderful reception by the public was Coverdine.

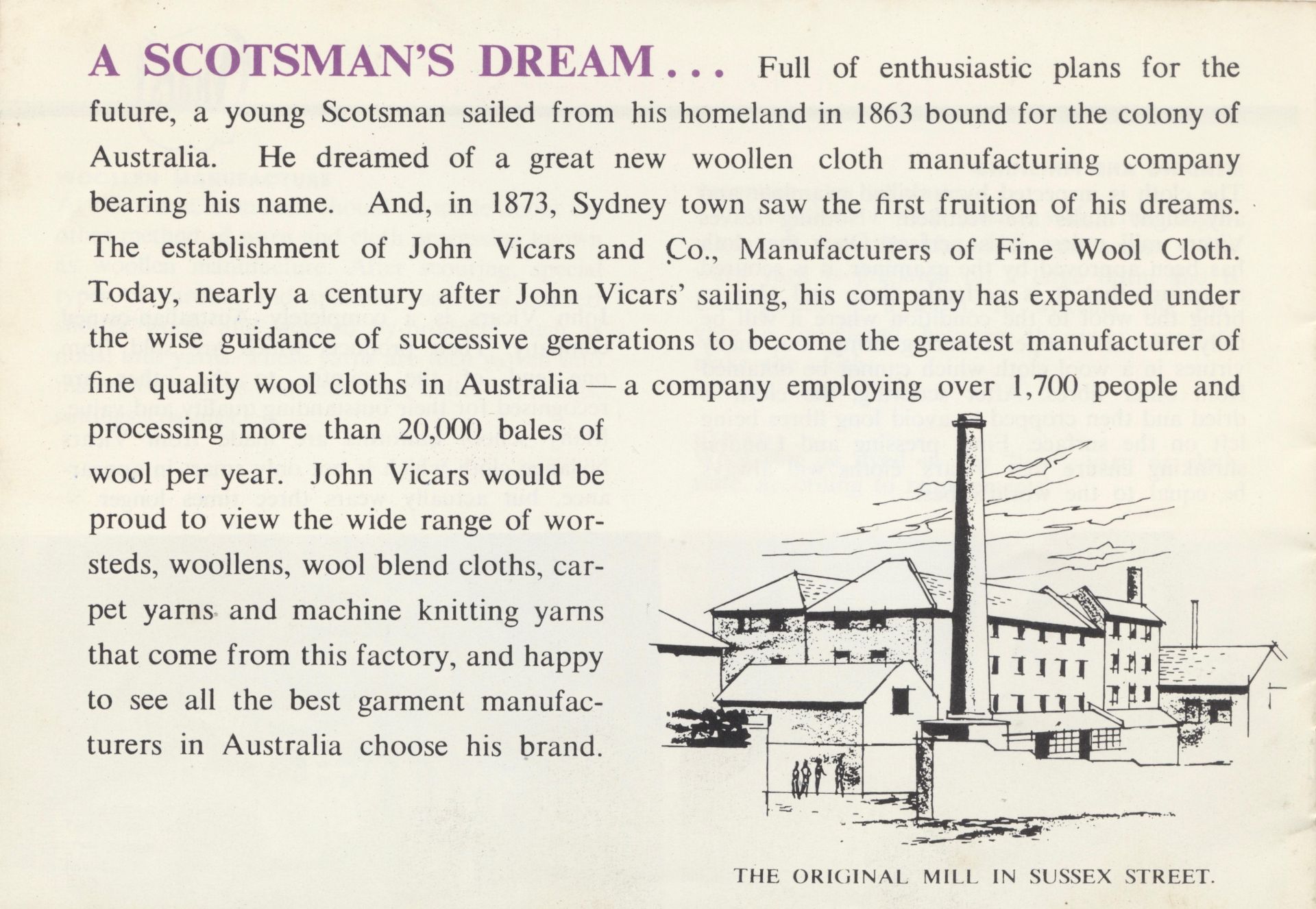

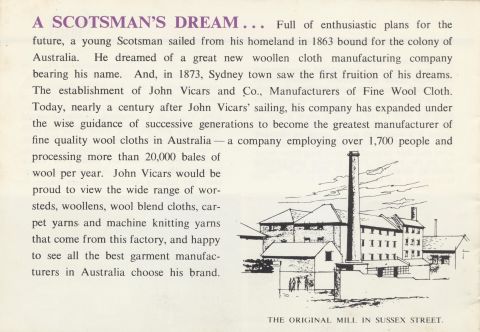

Coverdine was a pure wool 16-17 ounce fabric made from two-fold (two yarns twisted together) super-fine Merino yarn made exclusively for us by our good friends, John Vicars & Co of Sydney.

It was way ahead of any other cloth in this country for handle, performance and appearance.

And then came Si-Ro-Set and the position of creases became permanently fixed. Before Si-Ro-Set, the position of the crease edge changed slightly every time a trouser was pressed and the area of the crease wear was spread as a result – but with Si-Ro-Set, the crease stayed put, the wear was concentrated along a long narrow area and we had crease edge problems in our wonderful Coverdine.

A little nylon made all the difference – without loss of comfort or appearance, Coverdine became outstanding for its tough, hardwearing abilities.

And it became a yardstick for other cloths. As other fabrics have been added to the range, they’ve had to compete against Coverdine’s wearing qualities and well earned reputation.

DO YOU KNOW or FJ daily staff bulletin from 1970